This project was made after I saw a similar lamp made in ceramic and I thought it would look nice made of wood

This picture shows all of the segments glued into rings for the actual lamp.

This shows the segments having been glued into the two halves.

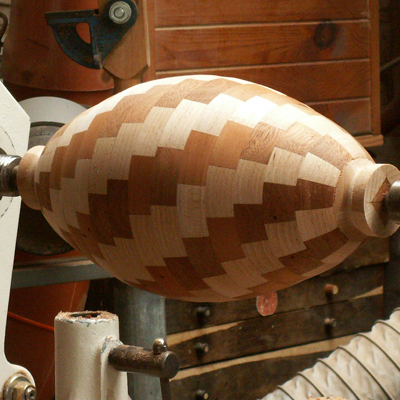

Here you can see the main body of the lamp having the two halves glued together and turned.

This shows me lining up the drill centre ready to bore the hole right through.

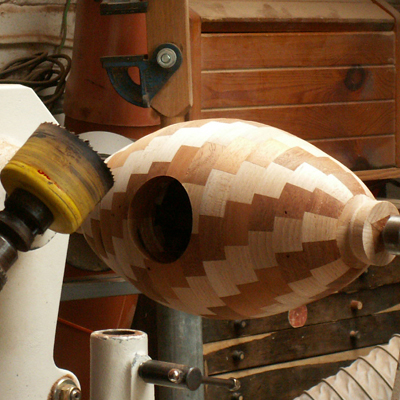

This shows me having used the hole cutter freehand.

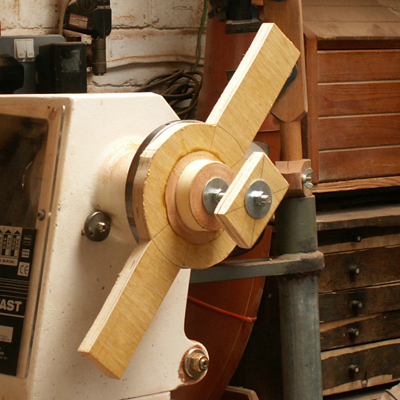

Here you can see a jig I made up to hold the body of the lamp so that I could counter turn

the body of the lamp to insert the segmented tube through the centre.

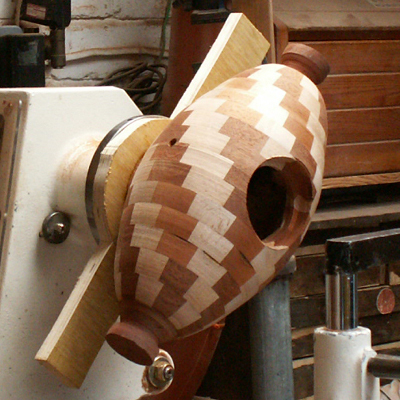

Here you can see the actual counter bore.

You can also see a hole which is in the top and bottom for the flex to run through.

You can also see that I have not finished the body of the turning by the glue line on some of the segments.

This picture shows the centre tube having been fixed and two waste blocks put in to stop break out of the sides of the central tube.

Here you can see the lamp roughly finished, all but the ends.

This shows the finished article on its base plinth which is let into a rebate which is cut into the bottom of the body.

The Finished lamp with a shade.

My intention when parting off of the lathe was to take it down each end to a reasonable size.

Unfortunately I had a dig in and it prematurely came off of the lathe, and on hitting the bed of the lathe the body suffered a nasty bruise.

I remembered seeing on television that if you used a damp cloth and a hot iron you could reduce the indentation, and whilst it did not reduce the indentation completely, you really have to look for it to see it.

This is a handy tip tp remember.